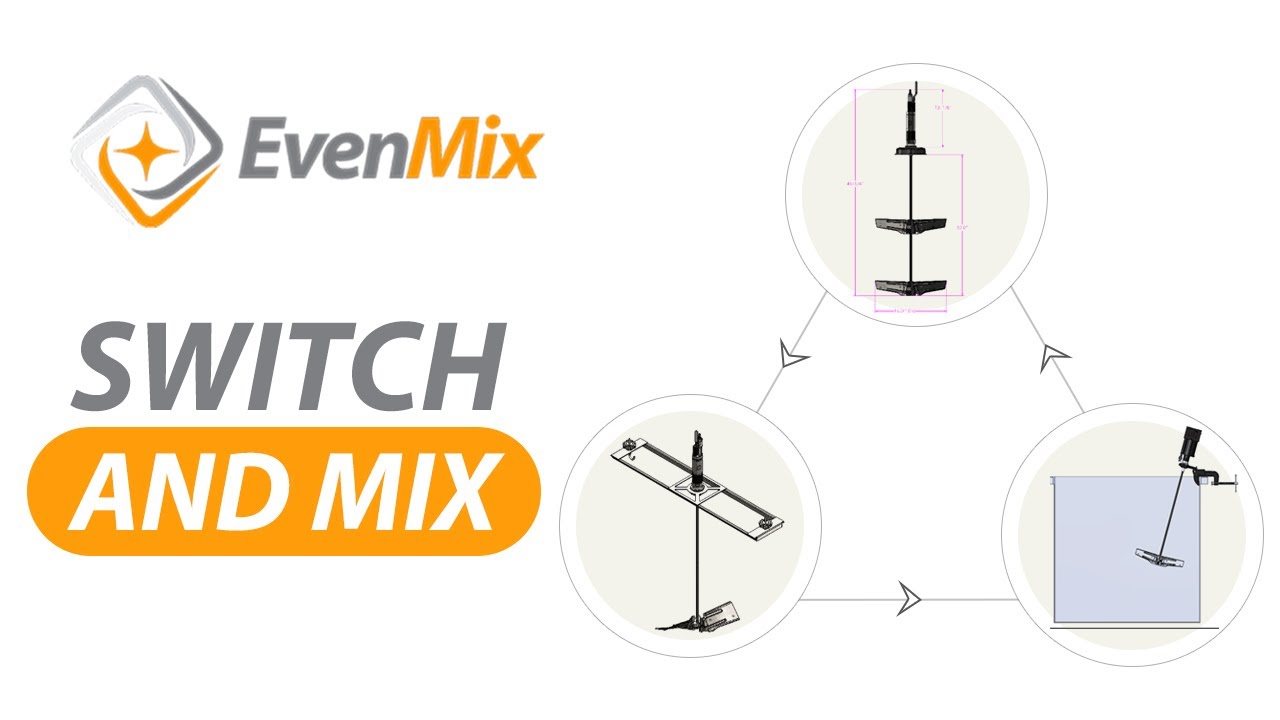

EvenMix specializes in advanced mixing solutions that have wide-ranging applications in various industries such as pharmaceuticals, chemicals, food and beverages, and more. The EvenMix technology is based on a patented mixing element design that delivers efficient, homogeneous mixing while minimizing energy consumption.

The Versatility of EvenMix’s Technology

One of the primary strengths of EvenMix’s technology is its versatility. The technology’s modular design allows for customization to cater to specific industry requirements. Here are some ways in which technology of EvenMix can be tailored to different sectors:

1. Pharmaceutical Industry

In the pharmaceutical industry, precision and consistency are paramount. EvenMix’s technology can be customized to meet the stringent mixing requirements of pharmaceutical formulations. It ensures that active ingredients are evenly distributed, leading to the production of high-quality medicines.

2. Chemical Industry

Chemical processes often demand specialized mixing solutions to prevent unwanted reactions or ensure proper blending. EvenMix’s technology can be configured to handle various chemical compositions, making it suitable for diverse chemical applications.

3. Food and Beverage Industry

The food and beverage industry has unique mixing needs, from gentle blending of ingredients in sauces to vigorous mixing of beverage concentrates. EvenMix’s technology can be adjusted to cater to the specific viscosity and density of various food products.

4. Environmental Applications

In environmental and wastewater treatment applications, efficient mixing is vital for the effective treatment of pollutants. EvenMix’s technology can be adapted to optimize mixing processes, contributing to a cleaner environment.

The Customization Process

Customizing EvenMix’s technology for specific industry needs involves a collaborative approach. Here’s how the process typically works:

Step 1: Needs Assessment

The first step is to assess the specific requirements of the industry in question. EvenMix’s team of experts works closely with clients to understand their unique mixing challenges.

Step 2: Design and Configuration

Based on the needs assessment, EvenMix’s engineers design a customized mixing solution. This may involve modifying the mixing element design, adjusting motor specifications, or integrating specialized sensors and controls.

Step 3: Testing and Optimization

Once the customized solution is implemented, rigorous testing and optimization take place. This ensures that the technology meets the industry’s standards for efficiency, quality, and safety.

Step 4: Installation and Support

EvenMix provides comprehensive support during the installation phase and offers ongoing assistance to ensure the technology operates at peak performance.